gipuzkoakultura.net

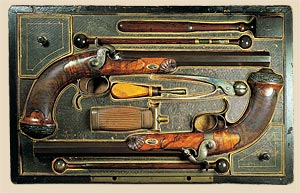

The transfer of the customs posts from the Ebro river to the sea and Irun (1841), the "O'Donnell Law" which aided the free sale of arms in the Iberian peninsula (1860), the adoption of new technologies, the opening of foreign markets, mainly in the Americas and Europe, and the disappearance of the rigid guild system, all combined to make the second half of the nineteenth century a golden age for the metal processing industry.

En los años siguientes los talleres y las fábricas de productos metalúrgicos proliferan, crecen y se renuevan. La producción de armas aumenta, y lo mismo ocurre con otros productos como clavos, tornillos, puntas de París, herramientas, etc. Esto trae consigo una mayor demanda de materias primas y es así como nacen las grandes fundiciones.

This is the case of S.A. Aurrera in Eibar, which was founded in 1883 at the initiative of a group of industrialists from the town, who prepared cast iron in two cupolas to supply the array of small manufacturers of high-quality arms, who had previously been dependent on French and Belgian imports. A similar case is that of Romualdo García who founded San Pedro de Elgoibar in 1877 to manufacture iron from charcoal. Their numbers gradually swelled with the appearance of other foundries such as Molinao in Pasaia, Fundición Fossey in Lasarte and the Real Compañía Asturiana de Minas, which built a lead foundry in Errenteria using the ore from the San Narciso mine in Irun, as well as others which formed a constituent part of self-contained companies such as Union Cerrajera, C.A.F., and Patricio Echeverría.

A common feature of all of these foundries was their low volume and production capacity in general terms, but they nonetheless employed a large number of operators and had the largest capital investments in Gipuzkoan industry, if we exclude a handful of highly-capitalised giants like the paper industry. According to the Industrial Census of 1915 only about ten metal enterprises had more than a hundred employees, and there were a large number which had less than ten. (LUENGO TEIXIDOR, 1990)

| Company Name | Workers |

| Sociedad Española de Construcciones Metálicas (Beasain) | 960 |

| Unión Cerrajera de Mondragón (Arrasate) | 870 |

| Orbea (Mallabia) | 347 |

| Garate, Anítua y Cía (Eibar) | 304 |

| Unión Cerrajera (Bergara) | 201 |

| ábrica de Cañones (Soraluze) | 188 |

| Trocaola, Aranzabal y Cía (Eibar) | 143 |

| Aizmendi (Eibar) | 126 |

| Fábrica de Plomo de Capuchinos (Errenteria) | 114 |

| Fundiciones Molinao (Pasaia) | 104 |

With the introduction of this new source of energy, arms manufacture attained record levels. In addition to Orbea, Larrañaga and Joaristi, the main manufacturers, other new names appeared, such as Victor Sarasqueta, Arizmendi, Trocaola, Aguirre, Zamacola y Cía, Crucelegui, Anitua, Beristain, etc. By 1906, the arms industry employed 54% of the workforce of Eibar, 50% in Soraluze-Placencia (where the former Euskalduna, now renamed S.A. Placencia de las Armas, gave work to 180 operators), and 11% in Elgoibar (AGIRRE KEREXETA, 1987). Eibar was by now recognised as the main arms manufacturing town on the Iberian peninsula.

A range of new products were manufactured as a result, including bicycles (G.A.C. in 1925; Orbea in 1929), sewing machines (Alfa in 1927), machine tools (Parabán y Cía, Orbea y Larrañaga, Juan Esperanza, Cruz, Ochoa y Cía, Estarta and Ecenarro in 1924), electrical appliances (Anitua e Hijos, Solac), screws (Aguinaga, Lete, Egaña and Madina); electrical apparatuses (Hormaechea), domestic utensils (Elma), forging and stamping (Garaciaga), machine-tools (Arriola y Cía, Forjas de Elgoibar, Alcorta, Unzueta y Cía, Mugarza, Ugarte y Cía, Crucelegui Hnos), locks (La Industrial Mondragonesa and Metalurgica Cerrajera) and hardware (Roneo and Altuna y Garay).

The dominance of the arms industry, which had been the main occupation of the Lower Deba area, was over and the result was a trend which to mark the industrial fabric of the region: extension and reorientation of production towards newer and more innovative markets.

Nonetheless, the most important single activity was still arms manufacture. In the mid 1920s, the manufacture of arms and its auxiliary industries accounted for 80% of the processing industry, but other specialisations were emerging, such as automobile accessories, electrical equipment and domestic appliances, as well as hardware, nuts and bolts, locks and machine tools. this new diversification was to cushion the eventual collapse of the arms industry.

Like so many other areas of everyday life, however, industrial progress was cut short by the Spanish Civil War; not only by the direct devastation caused of the conflict itself but also by its indirect impact in material, commercial and human terms. In many cases the survival of businesses or the handover to a new generation was blocked by the Franco administration's to any ideology it considered to be a threat to the regime (Basque nationalism, liberalism, communism, republicanism... etc.), leaving companies without managers or unwilling to take certain directions out of a fear of political purges. At the same time, international isolation and the economic blockade strangled industrial development during the first decade of the Franco regime. The large self-contained factories were in the best position to weather out this crisis and in the long run, some benefited by the protection their products enjoyed on the Spanish domestic market. Smaller companies, though, found it more difficult to ride out the years of isolation, and over subsequent years new industries were set up to meet the demand for products which had previously been imported.

As a result, despite destruction, scarcity of raw materials and political purges, by the mid-1950s, the metal industry once again stood at the head of Gipuzkoan industry and although not hegemonous, its pace of development a barometer of the province's economic health, reflecting better than any other industry developments such as the oil crisis of the 1970s, the restructuring of the 1980s and the commitment to new technologies, diversification and versatility of the last years of the century.

The list of companies dating from these years is long, but unquestionably the three flagships of the industry-for their long industrial career and their economic importance for the province-were Patricio Echeverría in Legazpi, C.A.F in Beasain and Union Cerrajera in Arrasate-Mondragón.